If you’ve seen a bright white roof, then you may be familiar with TPO roofing. As one of the most common roof types of big commercial facilities, TPO has some of the best energy savings for single-ply membrane roofing!

Here at West Roofing Systems, we’ve been installing Single-Ply Membrane Roofing for over 38 years. In this article, we cover everything you need to know about TPO roofing.

What Is Single-Ply Membrane Roofing?

[caption id="attachment_22019" align="alignright" width="300"] West Roofing Systems Installs Single Ply Membrane Roof[/caption]

West Roofing Systems Installs Single Ply Membrane Roof[/caption]

Single-Ply Membranes are sheets of rubber and other synthetics that can be ballasted, mechanically fastened or chemically adhered to insulation creating a layer of protection on your commercial facility.

While Single-Ply Membrane Roofing is one of the most well-known types of commercial roofing material, there are several types to fit your budget and facility needs. There are two main types of single-ply membrane commercial roofing: Thermoplastic Polyolefin (TPO) and Ethylene Propylene Diene Terpolymer (EPDM). They differ in their chemical makeup, how they are installed and their energy efficiencies.

What is TPO Roofing?

Thermoplastic Polyolefin is a single-ply roofing membrane that is one of the fastest growing commercial roofing systems on the market. TPO roofing systems are made up of a single layer of synthetics and reinforcing scrim that can be used to cover flat roofs.

TPO membranes are manufactured in sheets that are 10, 12 or 20 feet wide. These sheets are then rolled up and taken to the commercial facility. TPO has gained industry acceptance with the natural reflective surface to reflect UV rays. As reported by the National Roofing Contractors Association (NRCA) TPO takes up about 40% of the commercial roofing market share.

TPO Roofing Installation

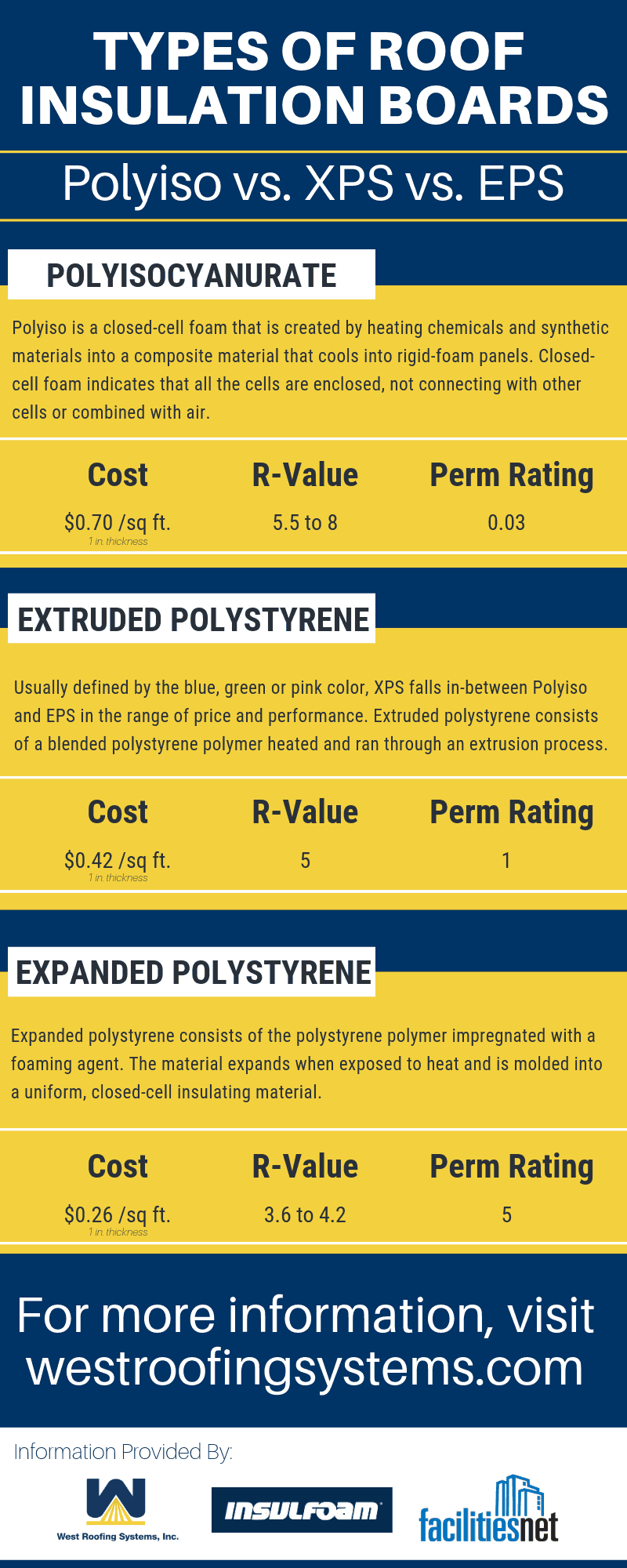

After the existing substrate is prepared, either by cleaning or removing the existing roof, the insulation is installed. There are a few types of insulation options the facility manager/owner can choose from:

- Polyisocyanurate (Polyiso) – The most used insulation type for roofing applications, Polyiso is more expensive but pay off with a higher R-value rating.

- Expanded Polystyrene (EPS) – With the highest R-value per dollar, EPS is used for roof, wall and floor insulation. EPS can be used with for ground contact and does not retain water over time.

- Extruded Polystyrene (XPS) – Usually defined by the blue, green or pink color, XPS falls in-between Polyiso and EPS in the range of price and performance. XPS is semipermeable with a perm rating of 1.

The TPO membrane can be attached to the cover board with a bonding adhesive or mechanically fastened. When the membrane is rolled out, the contractor then returns and uses a hot-air gun to hot air weld the seams together.

Here is a video of the West Roofing Systems team installing a TPO Single-Ply Membrane Roofing System:

TPO Roofing Costs

For an average 20,000 sq. foot commercial roof, it will usually cost between $3.50 and $7.50 per square foot in materials and labor to install a typical single-ply membrane commercial roofing system.

[caption id="attachment_22020" align="alignright" width="300"] West Roofing Systems Installs Single Ply Membrane Roof[/caption]

West Roofing Systems Installs Single Ply Membrane Roof[/caption]

To get the best rubber roofing prices, you will need to consider these key factors:

- The size of your roof

- The condition of the existing roof

- Access to roof

- Insulation choice

- Membrane choice

- Installation choice

- Roof penetrations

- Type of warranty

Advantages of TPO Roofing

If properly installed and maintained, a commercial single-ply membrane roof can last 30 years. There are quite a few other benefits of single-ply membrane roofing systems:

[caption id="attachment_22015" align="alignright" width="300"] West Roofing Systems Installs Single Ply Membrane Roof[/caption]

West Roofing Systems Installs Single Ply Membrane Roof[/caption]

- Customer Choice of Insulation – Since single-ply membrane roofing does not include the insulation factor, as a customer you have more options to choose from to insulate your facility’s roof.

- Class A Fire-Rated – TPO membranes and EPDM can achieve Underwriters Laboratories (UL) Class A fire resistance listings by adding fire retardant chemicals during the manufacturing process.

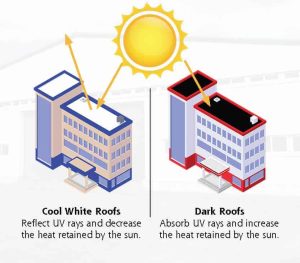

- Reflective or Retentive – TPO is generally white and highly reflective. On the other side of the spectrum, EPDM is often described as “Black Roofs,” due to the natural dark color of the membrane.

How TPO Roofing Saves Money

The most common TPO material is a bright white with high reflectivity properties. This bright white roof installation can reflect UV rays and heat from the building, saving money during the summer months from decreased energy usage to cool the building interior.

Single-Ply Membrane Roofing Systems have been the go-to roofing for commercial, industrial, and manufacturing facilities for decades.

West Roofing Systems, Inc. installs sustainable and efficient roofing systems for commercial, industrial, manufacturing and municipal buildings. In over 38 years, we have installed over 57,000,000 square feet of commercial Spray polyurethane foam (SPF), single ply membrane and other popular roofing systems.

If you are looking for maintenance, repair or replacement for your facilities roof, fill out our quote form for your free no-obligation commercial roof quote from our team of experts.

Article Here: TPO Roofing: Everything You Need To Know