Our sales team is asked every day, “How much does a single-ply membrane roof cost?” and it’s not easy to give just one answer. There are many factors that can affet rubber roofing prices; from the weather to the location to the material and installation.

In this article, we will review the average price of a single-ply membrane roof and break down factors that could change your price. Keep in mind that when you are looking to invest in a new roofing system, it’s a good idea to get multiple quotes from a couple contractors.

Single-Ply Membranes are sheets of rubber and other synthetics that can be chemically adhered or mechanically fastened to insulation or a cover board creating a layer of protection on your commercial facility.

Read More: Single-Ply Roofing Systems: Installation and Performance

For an average 20,000 sq. foot commercial roof, it will usually cost between $3.50 and $7.50 per square foot in materials and labor to install a typical single-ply membrane commercial roofing system.

To get the best rubber roofing prices, you will need to consider these key factors:

The Size of Your Roof

When a contractor is pricing a new roofing system, the economies of scale starts around 20,000 sq feet; which means after 20,000 sq. feet you can start saving money per square foot of roof.

[caption id="attachment_23998" align="alignright" width="300"] EPDM Roofing System[/caption]

Other size factors that can impact your cost also include:

- The logistics of moving equipment up to and across a large roof

- Debris removal costs

- Material transport costs – this cost can take up 2-3% of the total project costs

The Condition of Existing Roof

The condition of your existing roof will be a crucial factor in the cost of your new single-ply membrane roof. There are three options when dealing with the existing roof:

Clean and Prepare Existing Roof (no significant alterations) - $0.10 - $0.75 per sq. foot

When you have a solid roof that doesn’t require major modifications or corrections, the contractor will need to clean and prepare the roof, so the insulation adheres properly.

There are four ways a contractor can prepare a roof for single-ply membrane installation:

- Air Pressure Cleaning

- Powerwash

- Dry Vac/Ballast Removal

- Wet Vac for dirt, gravel and dust removal

Recovery Board Fastened on Top of the Existing Roof – $0.70 - $1.40 per sq. foot

Recovery boards are commonly used to cover and improve the application surface. This process could be used to cover joints and to provide a separation layer between the existing and new roofing systems.

Stripping and Removal of Roof - $1.00 - $2.00 per sq. foot

There are two main reasons a contractor would need to strip and remove your existing roof.

- A building can’t have more than two roofing systems. This means if you currently have two roofs, your contractor will need to remove them before installing your new roof.

- If your roof is damaged, saturated or unstable, your contractor will need to strip the existing roof to install a new working roof.

Access to Roof

[caption id="attachment_23977" align="alignright" width="300"] TPO Single-Ply Membrane Roofing[/caption]

Not all commercial roofs are flat; not all roofs can be walked on. Additional costs can occur when your contractor has limited access to the facility roof.

Height and distances of the roof can be multipliers for the cost of your single-ply membrane roof installation. Sloped roofs often require the contractors to use a man lift or repelling gear for single-ply membrane roof installation. Contractors may need to rent conveyance equipment such as a crane or passenger hoist to move the crew and equipment.

Insulation Choice

After the existing substrate is prepared, either by cleaning or removing the existing roof, the insulation is installed. In general, two layers of insulation are used.

There are a few types of insulation options the facility manager/owner can to choose from:

Polyisocyanurate (Polyiso)

Polyiso is the most commonly used insulation for roofing. It’s a rigid material that can be cut to size for installation. The R-Value for Polyiso lasts longer, and the aged R-Value is still higher than EPS and XPS.

Below are the costs for three different thicknesses:

- 1 in. - $1.40 - $1.75 per sq. foot in materials and labor

- 2 in. - $2.00 - $2.50 per sq. foot in materials and labor

- 3 in. - $2.80 - $3.15 per sq. foot in materials and labor

*Attached Polyiso cost associated with mechanical attachment would be based on industry average applications.

Expanded Polystyrene (EPS)

EPS can be used for roofing, walls or floor insulation, but more commonly used with concrete. You get more R-Value per dollar with EPS being the lowest cost insulation choice.

Extruded Polystyrene (XPS)

XPS insulation can be found in blue, pink or green and is most commonly used for wall insulation. This is probably what you think when you hear insulation because it is the middle of the road in terms of cost and R-Value.

Read More: Choosing Rigid Foam by Green Building Advisor

Membrane Choice

[caption id="attachment_23972" align="alignright" width="300"] EPDM Single-Ply Roofing System[/caption]

When you are considering single-ply membrane roofing, there are two types of membrane to choose from: TPO and EPDM.

TPO

Thermoplastic Polyolefin is a single-ply roofing membrane that is one of the fastest growing commercial roofing systems on the market. TPO roofing systems are made up of a single layer of synthetics and reinforcing scrim that can be used to cover flat roofs.

For an average 20,000 sq. foot commercial roof, it will usually cost between $1.90 and $3.50 per square foot in materials and labor to for a TPO membrane.

EPDM

Ethylene Propylene Diene Monomer is a single-ply membrane that consists of a synthetic rubber compound that allows it to be flexible. EPDM has been used on commercial roofing facilities since the 1960s and is considered a time-tested option.

For an average 20,000 sq. foot commercial roof, it will usually cost between $1.80 and $3.50 per square foot in materials and labor to for an EPDM membrane.

Infographic: TPO vs. EPDM Systems

Installation Choice

[caption id="attachment_23999" align="alignright" width="300"] TPO Installation[/caption]

When it comes to installing the membrane of your choice to your roof (whether it’s to the insulation or to a cover board), there are three ways to choose from: Ballasted, Fastened or Adhered. They each have their own advantages and disadvantages when it comes to price, longevity, and ease of installation.

Download: Roofing Contractor Quote Checklist

Ballasted

A Ballasted attachment is a low-cost option. It consists of laying down the membrane (TPO or EPDM) and covering it with gravel, pavers, river rock, and other similar materials. While this option can save you money (and look pretty cool), it adds up to 10 pounds per square foot onto your building structure. And as the rocks degrade over time, they can easily damage the membrane underneath. Maintaining this type system is very difficult since the ballast would need to be moved to see any deficiencies in the membrane.

Fastened

Fastened attachment is when the membrane (TPO or EPDM) is mechanically attached to the cover board with metals screws and plates. These are inserted along the seams of the membrane sheet.

Adhered

A chemically adhered membrane is rolled out onto the cover board after a bonding adhesive is applied. This method does not penetrate the membrane which alleviates the chance of leaks even more.

Cost Table

Depending on the type of membrane thickness of membrane and type of attachment, your cost could vary.

Below is a table of cost estimates based on an average size roof:

| 045 mils Thickness | 065 mils Thickness | |

| TPO | ||

| Ballasted | $1.90 - $2.35 per sq. foot | $2.00 - $2.50 per sq. foot |

| Fastened | $2.50 - $3.00 per sq. foot | $2.65 - $3.15 per sq. foot |

| Adhered | $2.75 - $3.25 per sq. foot | $2.85 - $3.50 per sq. foot |

| EPDM | ||

| Ballasted | $1.80 - $2.25 per sq. foot | $2.00 - $2.35 per sq. foot |

| Fastened | $2.00 - $2.25 per sq. foot | $2.20 - $2.70 per sq. foot |

| Adhered | $2.80 - $3.20 per sq. foot | $3.00 - $3.50 per sq. foot |

Roof Penetrations

[caption id="attachment_23979" align="alignright" width="300"] TPO Single-Ply Membrane around Roof Penetration[/caption]

Most commercial roofing systems have accessories attached such as A/C units, skylights, air vents, plumbing vents and more. These penetrations on the roof can be in the way of rolling out a straight section of membrane.

When the contractor approaches these penetrations with single-ply membrane roofing, they need to cut smaller membrane pieces to size and essentially building up the roof around the vents/units which takes up more time and can cost more money to work around.

Type of Warranty

When you install a new single-ply membrane roofing system, you will have a few warranty options. The three most common types of warranties include:

- Contractor’s Warranty - No expense or less than $1,000

- Manufacturer’s Product Warranty - Low cost and low coverage

- Manufacturer’s Full System Warranty - $0.08 - $0.15 per sq. foot

Single-Ply Membrane Roofing Systems have been the go-to roofing for commercial, industrial, and manufacturing facilities for decades. Contact West Roofing Systems today to talk to our expert staff about rubber roofing prices and your future Single-Ply Membrane Roofing System.

Original Post Here: Cost of Single-Ply Membrane Commercial Roofing (2019)

Heat

Heat

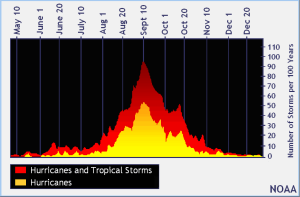

When is Hurricane Season?

When is Hurricane Season? Wind Damage

Wind Damage 3. Continue with Regular Maintenance

3. Continue with Regular Maintenance

Spray Foam

Spray Foam

Spray Polyurethane Foam (SPF) is an eco-friendly roofing option for commercial, industrial and manufacturing facilities. Spray Polyurethane Foam, more commonly referred to as SPF, is a material that is sprayed as a liquid so it can expand into a foam, creating a solid layer across an existing roof.

Spray Polyurethane Foam (SPF) is an eco-friendly roofing option for commercial, industrial and manufacturing facilities. Spray Polyurethane Foam, more commonly referred to as SPF, is a material that is sprayed as a liquid so it can expand into a foam, creating a solid layer across an existing roof.